A Complete Collection of Commonly Used Chemical Auxiliaries in Jeans Washing

Common auxiliaries for downward bleaching:

1)

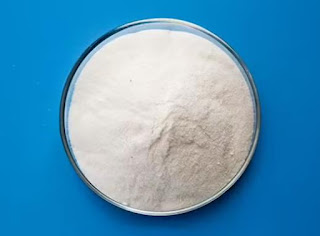

Sodium metabisulfite: milky white

powder. It is used for unbleaching after

potassium

permanganate solution has reached the bleaching degree when bleaching denim

fabric. No need to add hydrogen peroxide for assistance.

Contact

with sodium metabisulfite China manufacturer to

get sodium metabisulfite.

2) Sodium hypochlorite: a light green transparent liquid. Commonly known as floating water. Used for bleach Indigo blue of denim cloth surface.

3) Potassium permanganate: purple crystal. Usually mixed with water to form a liquid state. According to the required proportion of the cloth demand, phosphoric acid, potassium permanganate, and water can be mixed together to form a potassium permanganate solution. Used to bleach the attached pigment (indigo, vulcanization, etc.) of denim cloth surface fiber.

4) Hydrogen peroxide: hydrogen peroxide is used to unbleach after sodium hypochlorite has reached the bleaching degree when bleaching denim cloth.

5)

Oxalic acid: White transparent crystal. It is used for unbleach after potassium

permanganate has reached the bleaching degree when bleaching denim clot, and

hydrogen peroxide of the same quality needs to be added to assist in unbleach.

Common

auxiliaries for desizing:

1)

Caustic soda: milky white flake crystals. Also known as liquid alkali or flake

alkali. It mainly plays a role in refining during desizing. If dark colors

require re drawing, or if white embryo fabrics require high temperature cooking

and caustic soda before dyeing, it is also essential.

2) Soda ash: White powder. The function is the same as above.

3)

Jap oil: a light blue transparent liquid. Clean fibers and prevent staining.

4) Industrial laundry powder: white powder. The effect is the same as that of jap oil.

5)

Hydrogen peroxide: Transparent and pungent liquid. It mainly plays a role in

refining during desizing. If dark colors require re-drawing, or if white embryo

fabrics require high temperature cooking and desizing before dyeing, hydrogen

peroxide is also one of the commonly added additives.

6) Anti dye agents: There are usually two types: light blue liquid and gelatinous solid. Prevent denim indigo from falling onto the bay position, sand position, bag cloth or embroidery position during this process of washing water.

Common auxiliaries for fermentation and grinding:

1) Enzyme powder: white powder. During the dynamic operation of denim clothing in the washing machine, the fermentation makes the denim warp drop dye quickly under the physical action (denim warp is dyed with indigo) to produce irregular white spots on the denim cloth surface. Present a nostalgic and retro style. Many times, it is added as an auxiliary pumice during polishing.

2) Enzyme water: yellow brown liquid. It is usually used to remove the cilia protruding from the denim cloth after desizing, and it is also used for polishing and blooming when washing the denim of water refined cotton or some high-density cloth.

3) Acetic acid: Transparent and pungent liquid with a sour taste. Adjust the pH value of the water in the tank before applying the enzyme water. The pH value of enzyme water for hair removal is usually 4-4.5.

4) Urea: White circular crystal. It is used by some washing plants for removing wool from white embryo denim or yarn card clothing.

Common auxiliaries for whitening agents:

1) Caustic soda: before this process is started, if the bottom color of denim fabric is deep against the board, caustic soda can be added to the whitening agent for boiling to achieve the effect of fading and adding whitening agent to make the fabric more bright. If denim fabric has been flat, oxygen bleaching auxiliaries such as caustic soda, soda ash and hydrogen peroxide are not required.

2) Soda: same as above.

3) Hydrogen peroxide: same as above.

4) Jap oil: prevent denim indigo from falling and dyeing to the bay position, sand position, bag cloth or embroidery position during this process of washing water.

5) Whitening agent: after adding the whitening agent, the denim cloth surface will be more bright, and under the purple light, the denim cloth surface will have a bright effect.

Common auxiliaries for post-treatment:

1) Soft oil: There are several different forms of soft oil products in the market, such as soft ointment, soft oil essence, soft film, etc. But the purpose is basically the same. Mainly used for the softening treatment of jeans before washing water out of the tank.

2) Silicone oil: one type is a light blue liquid, one type is a milky white liquid, and there is also a high-concentration product in the form of a gel. Before washing the finished product out of the tank, it is added to make the fabric soft and smooth.

3) Brightener: milky white liquid. Add it before washing the finished product out of the tank to make the cloth surface more transparent and smooth.

4) Dilatant: mainly composed of two types: milky white and mixed yellow. Before washing the finished product out of the tank, it is added to make the fibers more fluffy, making the fabric feel comfortable and soft. But most are only effective for pure cotton fabrics.

5)

Glassy water: mixed yellow liquid. The biggest characteristic of glassy water

is its high quality. Glassy water is the precursor of many hardening agents.

Prior to 2005, many washing products added this additive when they needed

hardening effects. However, various hardening agents have gradually replaced

glassy water on the market. The main function of adding glassy water before the

finished denim is to make the feel of the finished denim more firm after

drying.

Common auxiliaries used by various process departments:

1) Resin: mixed yellow liquid. Mainly used for shaping wrinkles in the wrinkling department. Before wrinkling, soak the denim products in a container mixed with resin and water for about 20 minutes before removing and drying until 70% or 80% of them are ready for wrinkling. After the wrinkling is completed and baked in a high-temperature oven, the residual resin will completely adhere to the denim fabric and maintain the shape before the oven to adhere and shape, thus achieving the effect of permanently shaping the wrinkling position.

2) Phosphoric acid: Transparent liquid. Mainly used for mixing potassium permanganate and water to form potassium permanganate solution in the monkey part. In potassium permanganate solution, phosphoric acid plays a catalytic role. Usually, a blending ratio is added when spraying heavy bays or black cow fabric bays. Light bay or light indigo fabric bay does not need to be added.

3) Fixing agent: mixed yellow liquid. Used for fixing the color after dyeing denim.

4)

Sodium chloride: commonly known as salt. Add during the dyeing process. When

dyeing cellulose fibers with direct dyes, salt plays a dyeing promoting role.

Sodium

metabisulfite is one of the most important chemical auxiliaries for jeans

washing.

Comments

Post a Comment